Large Commercial Production Freeze Dryers

Large Commercial Freeze Dryers customized to fit your process.

Designed to fit YOUR budget, YOUR process and made to scale with you

Us Freeze Dry Large scale production dryers are customizable to fit your specific needs. These machines can accommodate a wide variety of products. Designed once we hear your process, we know these machines will save you money upfront, and through day in and day out production, in saved man hours, efficient safe cleaning, Sized just for you.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButton

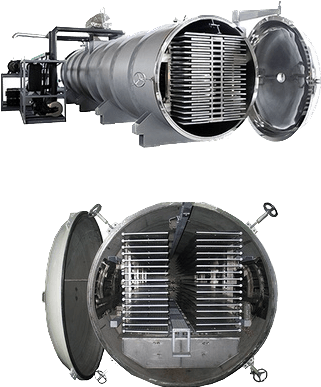

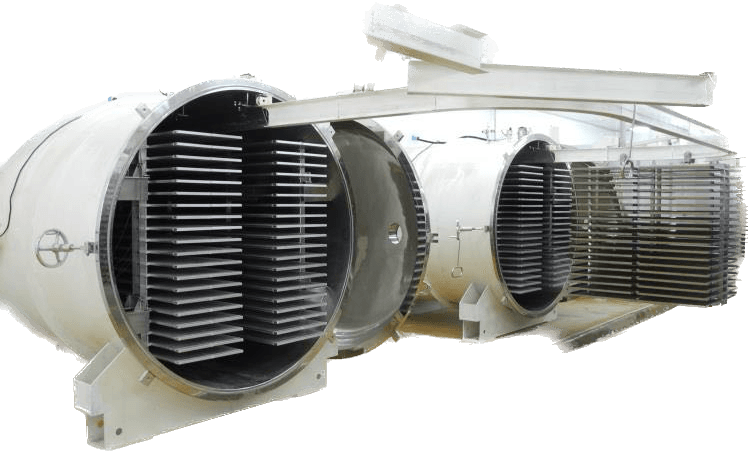

Radiant Dryers

-

Customizable Redundancy

With options to build redundancy in the compressors, and vacuum pumps, you can eliminate downtime, for repair or maintanace.

-

Sanitation

With optional CIP or SIP for cleaning ensuring if you dry multiple products, there is no risk of cross contamination.

-

HVT Radiant Heating

Aerospace grade aluminum alloy allows for even double sided Radiant heating where all the shelves are within a degree of the Shelf setpoint. Radiant Drying offers a more even drying opposed to Conductive drying. Ensuring faster runtimes, and reduced energy costs. Outdated walk in Dryers are limited in how the heat transfer from the heating element to product is obtained. This is what causes the longer runtimes. The difference in heat from the conductive tray the product rests on, vs the Radiant heat recieved from above.

-

Without in SITU Freezing

The product is frozen in a seperate freezer, allowing both freezeing of the next batch, and freeze drying of the current batch to happen simultaniously

-

Condenser coils for Ice Capture

Using a high efficiency mixed refrigeration mix allows for a long service lifem with high heat tranfer effiency allowing for faster sublimation, allowing you to drive heat faster to the product without experiencing collapse.

-

Control Package

Our controls are flexible in allowing both manual and automatic mode during drying. We offer the ability to remote operate the machine through a secure connection. Adins can set user level access and passwords.

-

Optimized Process Control

Precise control of the vacuum and heating during each set point. Ability to control each step and ramp rate.

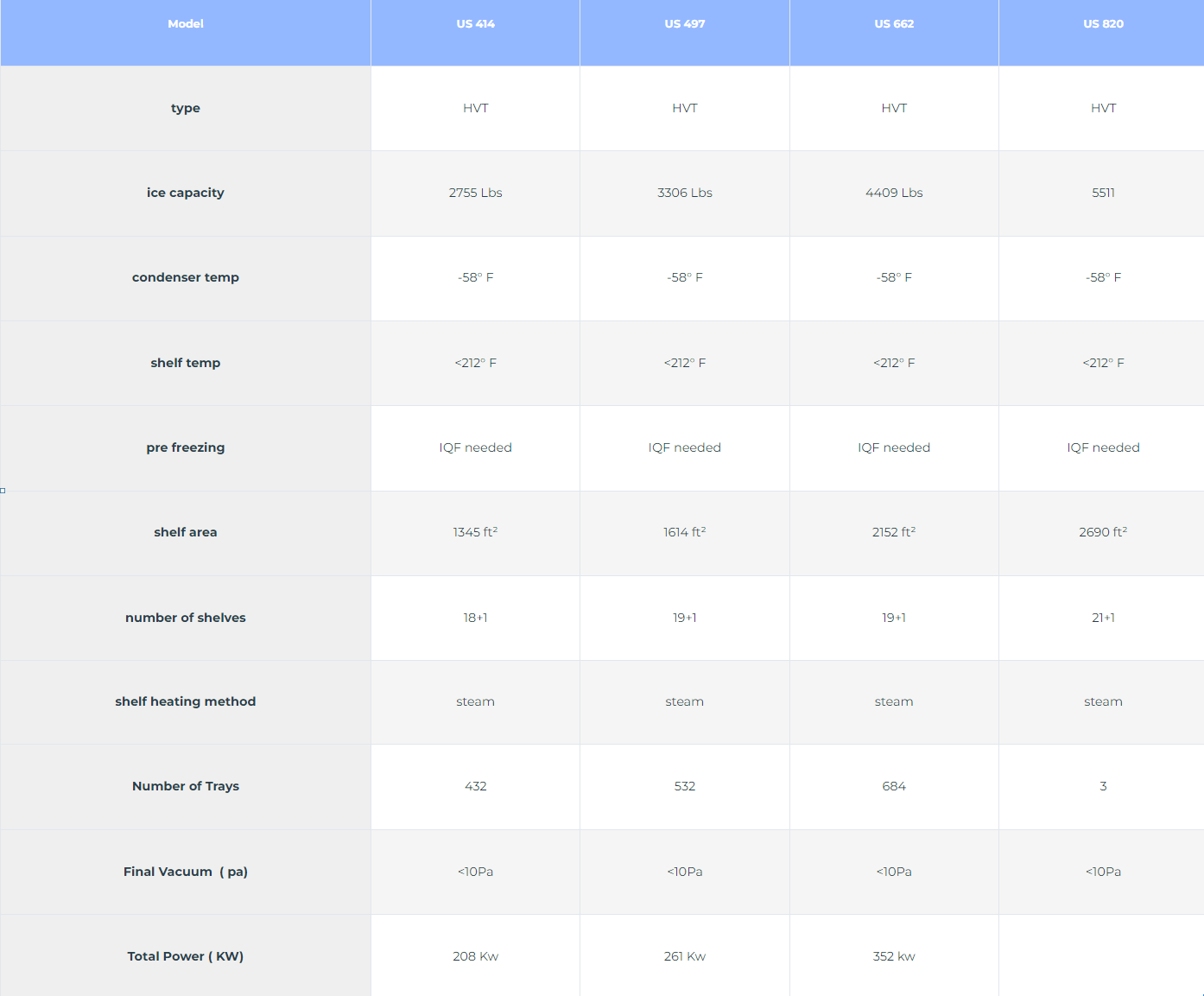

| Model | US 414 | US 497 | US 662 | US 820 |

|---|---|---|---|---|

| type | HVT | HVT | HVT | HVT |

| ice capacity | 2755 Lbs | 3306 Lbs | 4409 Lbs | 5511 |

| condenser temp | -58° F | -58° F | -58° F | -58° F |

| shelf temp | <212° F | <212° F | <212° F | <212° F |

| pre freezing | IQF needed | IQF needed | IQF needed | IQF needed |

| shelf area | 1345 ft² | 1614 ft² | 2152 ft² | 2690 ft² |

| number of shelves | 18+1 | 19+1 | 19+1 | 21+1 |

| shelf heating method | steam | steam | steam | steam |

| Number of Trays | 432 | 532 | 684 | 3 |

| Final Vacuum ( pa) | <10Pa | <10Pa | <10Pa | <10Pa |

| Total Power ( KW) | 208 Kw | 261 Kw | 352 kw |

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

-

Customizable Redundancy

With options to build redundancy in the compressors, and vacuum pumps, you can eliminate downtime, for repair or maintanace.

-

Sanitation

With optional CIP or SIP for cleaning ensuring if you dry multiple products, there is no risk of cross contamination.

-

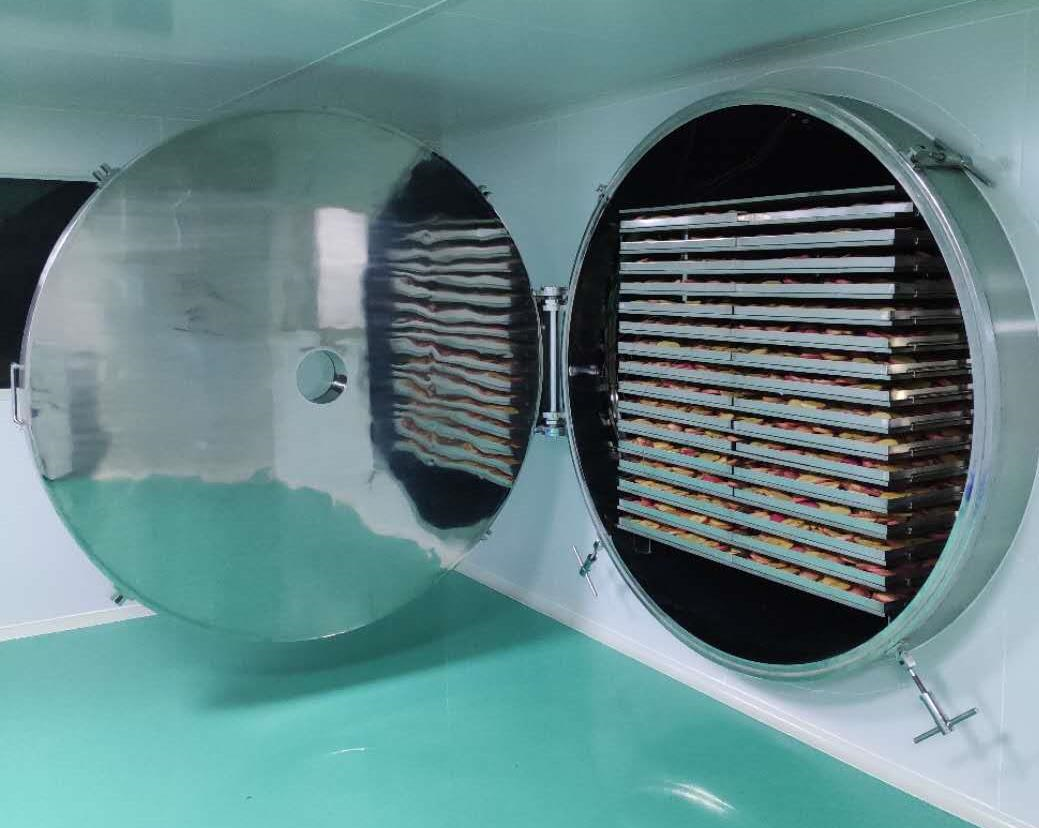

Conductive heating

Aerospace grade aluminum alloy allows for even double sided Radiant heating where all the shelves are within a degree of the Shelf setpoint. Radiant Drying offers a more even drying opposed to Conductive drying. Ensuring faster runtimes, and reduced energy costs. Outdated walk in Dryers are limited in how the heat transfer from the heating element to product is obtained. This is what causes the longer runtimes. The difference in heat from the conductive tray the product rests on, vs the Radiant heat recieved from above.

-

in SITU Freezing

This machine can freeze the product in the freeze dryer and aids in drying processes that must remain in sub freezeing temps through the process

-

Condenser coils for Ice Capture

Using a high efficiency mixed refrigeration mix allows for a long service lifem with high heat tranfer effiency allowing for faster sublimation, allowing you to drive heat faster to the product without experiencing collapse.

-

Control Package

Our controls are flexible in allowing both manual and automatic mode during drying. We offer the ability to remote operate the machine through a secure connection. Adins can set user level access and passwords.

-

Optimized Process Control

Precise control of the vacuum and heating during each set point. Ability to control each step and ramp rate.

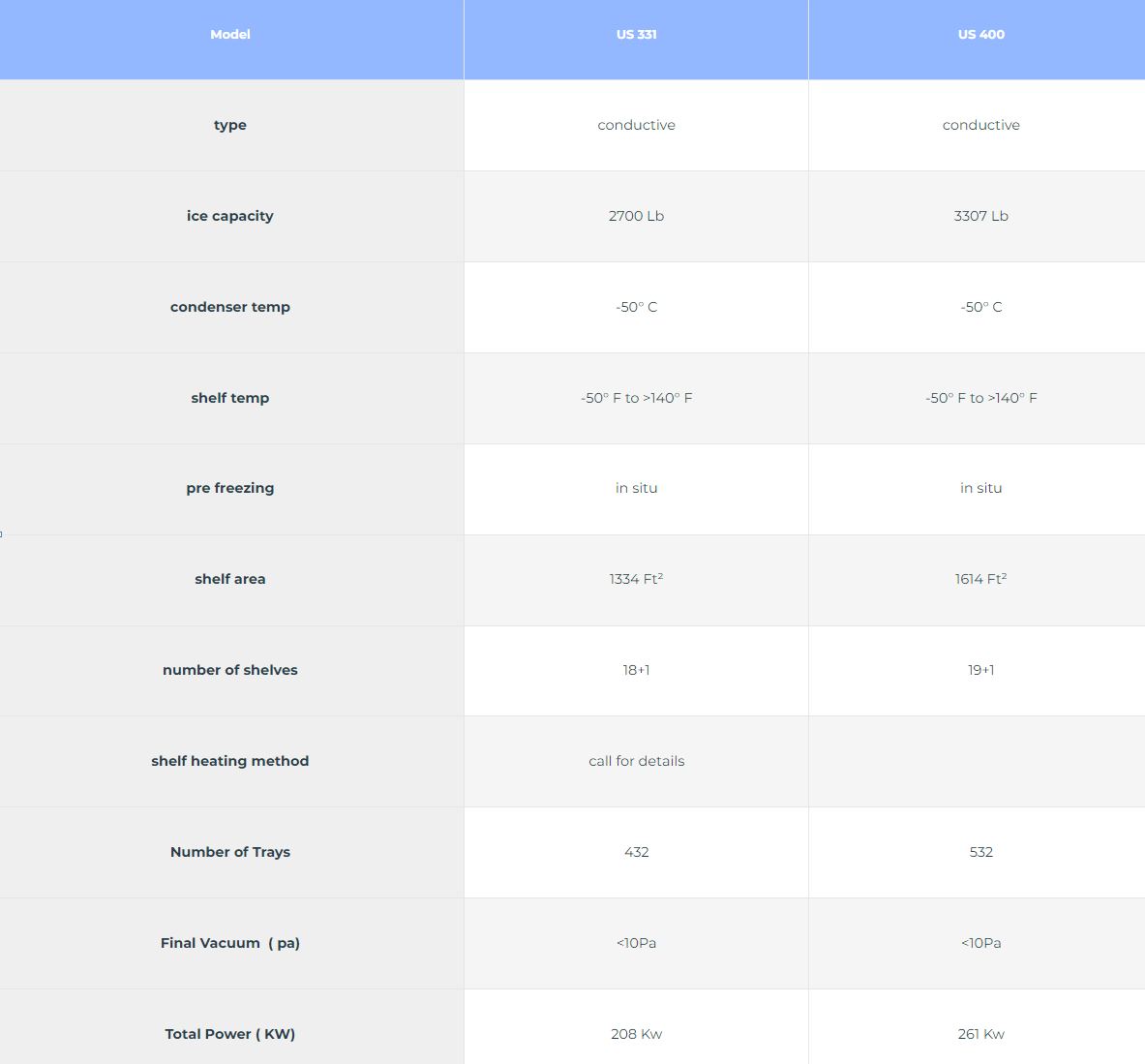

Conductive Freeze Dryers

| Model | US 331 | US 400 |

|---|---|---|

| type | conductive | conductive |

| ice capacity | 2700 Lb | 3307 Lb |

| condenser temp | -50° C | -50° C |

| shelf temp | -50° F to >140° F | -50° F to >140° F |

| pre freezing | in situ | in situ |

| shelf area | 1334 Ft² | 1614 Ft² |

| number of shelves | 18+1 | 19+1 |

| shelf heating method | call for details | |

| Number of Trays | 432 | 532 |

| Final Vacuum ( pa) | <10Pa | <10Pa |

| Total Power ( KW) | 208 Kw | 261 Kw |